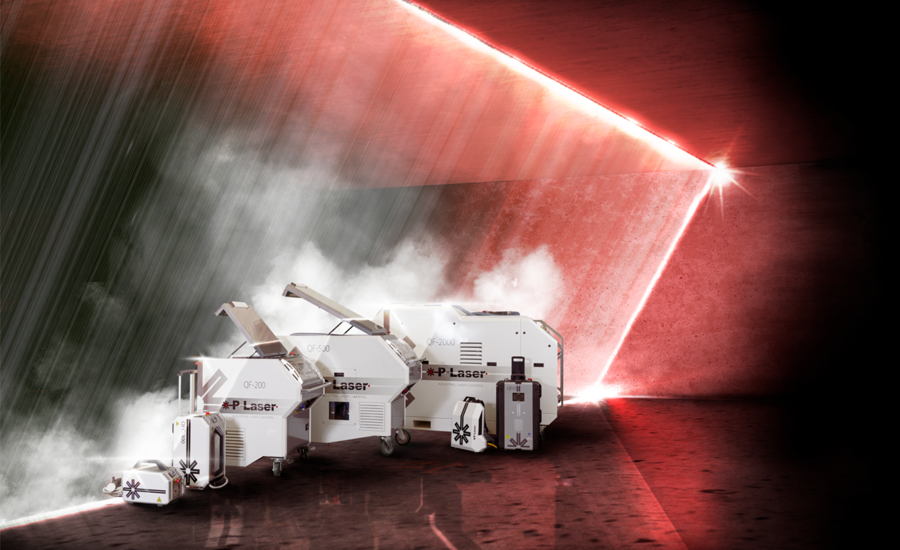

Industrial Laser Cleaning Applications

Laser cleaning is a modern, convenient method of metallic cleansing. It uses laser light to eliminate rust, paint, and dirt from surfaces. This technique is becoming increasingly popular because it’s fast, accurate, and environmentally safe.

What is Laser Cleaning?

Laser cleaning uses a unique laser beam to smooth metallic surfaces. The laser heats rust, paint, or dust on the metallic floor. When heated, these materials break free from the metal or freeze. This leaves the metallic floor easy and ready for similar use.

How Does Laser Cleaning Work?

Here, laser cleaning works

Laser light control:

The laser beam is directed at the metallic surface. You can exchange the strength of the laser depending on how much you want to clean.

Pollution That Causes Shivering:

The laser melts rust, paint, or dust. The laslaser’sat causes those unwanted substances to soften or destroy far away from the steel.

Disposal:

Once the rust or dust has decreased, the metallic floor can be blown or vacuum-dried. This cleans it without leaving a mess.

Why is Laser Cleaning Useful?

Laser cleaning has many benefits that make it superior to older strategies, which include chemical remedies or sandblasting.

Accuracy:

Laser cleaning can be precise. It can target small areas without compromising different elements, which is extremely useful for cleaning small, sensitive surfaces.

Pace:

Laser cleaning works quickly. It can remove more significant regions quicker than other techniques, which saves time and facilitates the method’s acceleration.

Not the environment:

Laser cleaning does not use harmful chemical compounds, making it safer for the environment and people.

Where is Laser Cleaning Used?

Laser cleaning is used in many distinct industries. Here are a few examples:

Manufacturing:

Industrial laser cleaning machine manufacturers produce steel elements before they are covered. The machine washes away rust and dust to enhance paint adhesion, contributing to highly satisfactory merchandise.

Aerospace:

In the aerospace enterprise, preservation lasers assist in managing aircraft parts. They remove vintage paint and dust without damaging delicate plane parts, making the aircraft secure and efficient.

Automotive:

Car production involves laser coaching of elements earlier than meeting or restoring. Remove rust and dust from parts to keep everything aligned and in top operating order. This makes the vehicles more dependable and sturdy.

Construction:

Construction systems regularly become grimy and rusty from overuse. Laser cleaning facilitates the removal of dirt and rust, retaining the device in its correct condition. This enables machines to last longer and reduces the need for upkeep.

Marine:

Exposure to water regularly results in the rusting of ships and marine gadgets. Laser cleansing enables the elimination of rust and corrosion from these surfaces. This protects the gadget and keeps it jogging easily for a long time.

How to choose the suitable laser cleaning device

When picking a laser cleaning machine, there are a few things to think about:

Laser Power:

The strength of the laser is essential for how well it cleans. A more robust laser can quickly handle more challenging cleaning jobs and clean large areas. Investigate a device with an adjustable electrical system.

Portability:

Choose a portable one if you need to move the laser cleaning machine around. A small, lightweight machine is more accessible to transport and use in different places.

Easy to Use:

The machine should be easy to control. Look for one with simple controls that allow you to change settings quickly and manage the cleaning process.

Safety Features:

Safety is paramount when using lasers. Choose a machine with safety features like shields and automatic shut-off systems to keep the operator safe.

Maintenance and Support:

Pick a machine that is easy to maintain and has good customer support.

Benefits of Laser Cleaning

Laser cleaning gives many blessings, e.g……..

Effective Cleaning:

Laser cleaning does a notable job of eliminating rust, paint, and dust from surfaces. It cleans thoroughly, keeping the metal in its right situation.

Minimal waste:

Laser cleaning produces little or no waste. It does not use chemical compounds or abrasives, making it an easy and efficient technique.

Cost savings:

While shopping for a laser cleaning system can be costly, it no longer prevents much cash in the long run. The system removes the want for chemical preservation and reduces maintenance fees.

Quick cleanup:

Laser cleaning is faster than any other technique. This approach requires less time spent cleansing and more time spent on other essential tasks.

Conclusion

Laser cleaning is a modern and powerful method of cleansing metals. It’s accurate, quicker, and better for the environment than older techniques. This method of cleansing is used in many industries, including the production, aviation, car, creation, and marine sectors.

When choosing a laser maintenance tool, you must consider factors such as electricity, portability, ease of use, protection capabilities, and upkeep necessities. With a suitable device, you can preserve your device quickly, rust-free, and in splendid shape for the long term.