How to Set the Timing on an Accucraft Ruby: A Comprehensive Guide

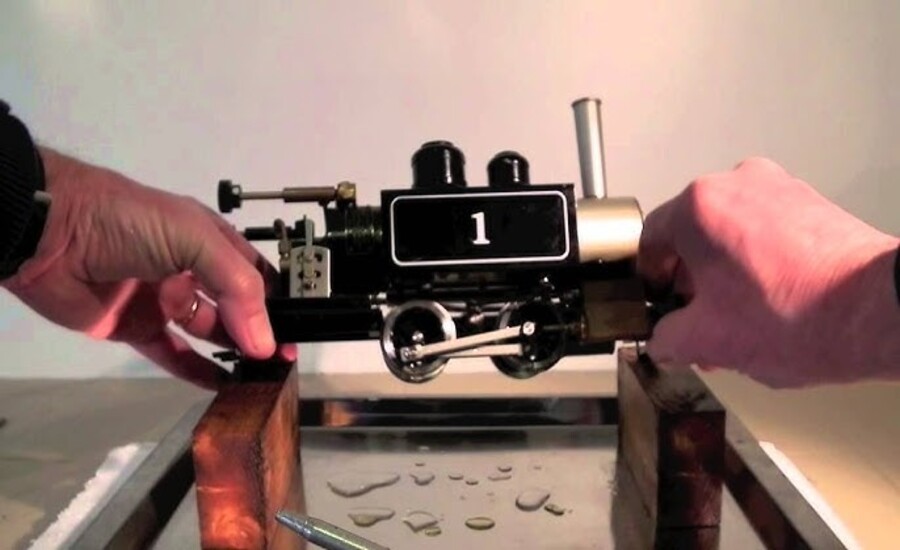

The Accucraft Ruby is a popular model steam locomotive, cherished by enthusiasts for its precision and performance. Setting the timing on this locomotive is crucial for ensuring optimal operation and performance. Furthermore, this comprehensive guide will walk you through the process of setting the timing on an Accucraft Ruby, detailing every step and offering insights into why timing is important.

Understanding the Basics of Steam Locomotive Timing

Before diving into the specifics of setting the timing on the Accucraft Ruby, it’s essential to grasp the fundamentals of steam locomotive timing. Timing in a steam locomotive refers to the synchronization of the valve gear with the motion of the pistons. This synchronization is vital for the engine to run smoothly and efficiently.

In steam locomotives, the valve gear controls the steam distribution to the pistons. Proper timing ensures that steam is admitted and exhausted at the correct moments in the engine’s cycle, allowing for smooth operation and maximizing power output. Incorrect timing can lead to inefficient performance, excessive wear, and potential damage to the engine.

Preparing Your Accucraft Ruby for Timing Adjustment

Before you begin adjusting the timing on your Accucraft Ruby, you need to prepare the locomotive. Proper preparation ensures that you can make precise adjustments and avoid damaging any components.

- Ensure the Engine is Cool: Timing adjustments should be made when the engine is cool to prevent any thermal expansion from affecting your adjustments. This also ensures safety, as hot components can cause burns or other injuries.

- Clean the Engine: Dirt and debris can interfere with the timing process. Clean the locomotive thoroughly, paying special attention to the valve gear and piston components. Use a soft brush or compressed air to remove any accumulated dust or grime.

- Gather Necessary Tools: You’ll need a few tools for this process, including a small screwdriver, a timing gauge or caliper, and possibly a set of wrenches. Ensure that you have the correct size and type of tools to avoid damaging the locomotive.

Accessing the Valve Gear on the Accucraft Ruby

To adjust the timing, you first need to access the valve gear. The valve gear is typically located within the locomotive’s chassis and is responsible for controlling the steam flow to the pistons.

- Remove the Body Shell: Carefully remove the body shell of the Accucraft Ruby to access the internal components. Furthermore, this usually involves unscrewing several small screws. Be cautious not to damage any delicate parts during this process.

- Locate the Valve Gear: Once the body shell is removed, locate the valve gear. It is usually positioned near the pistons and consists of several interconnected components, including the eccentric rod and valve.

- Inspect the Valve Gear: Check for any signs of wear or damage. Ensure that all components are properly lubricated and functioning smoothly. Address any issues before proceeding with the timing adjustments.

Setting the Timing on the Accucraft Ruby

Setting the timing involves adjusting the position of the valve gear to synchronize it with the pistons. This process requires careful adjustment and verification to ensure accurate timing.

- Identify the Timing Marks: The Accucraft Ruby should have timing marks or indicators on the valve gear. These marks help you align the components correctly. Consult the locomotive’s manual for the specific location of these marks.

- Adjust the Eccentric Rod: The eccentric rod is crucial for controlling the timing of the valve gear. Loosen the bolts securing the eccentric rod to the crankshaft and adjust its position according to the timing marks. This adjustment will change the phase of the valve gear relative to the pistons.

- Check the Piston Movement: With the eccentric rod adjusted, manually rotate the wheels to observe the piston movement. Ensure that the pistons are moving smoothly and that the valve gear is providing the correct amount of steam to the pistons at the right time.

- Fine-Tune the Timing: Make small adjustments to the eccentric rod until the timing is accurate. Furthermore, this may require several iterations of adjustments and checks. Be patient and methodical in this process to achieve optimal timing.

Testing the Timing Adjustment

After making the initial adjustments, it’s crucial to test the timing to ensure that the locomotive performs correctly. Testing helps verify that the timing adjustments have been successful and that the engine runs smoothly.

- Reassemble the Engine: Carefully reattach the body shell and ensure that all screws and components are securely fastened. Check for any loose parts that could affect the performance of the locomotive.

- Conduct a Test Run: Perform a test run of the Accucraft Ruby to observe its performance. Pay attention to the smoothness of the operation, the responsiveness of the controls, and any unusual noises or behaviors.

- Make Further Adjustments if Necessary: If the locomotive does not perform as expected, recheck the timing adjustments and make any necessary refinements. It may take several test runs and adjustments to achieve perfect timing.

Common Issues and Troubleshooting

Timing adjustments can sometimes lead to common issues that may affect the performance of the Accucraft Ruby. Understanding these issues and how to troubleshoot them can help you resolve problems effectively.

- Engine Stalling or Hesitation: Furthermore, if the engine stalls or hesitates, it may indicate that the timing is off. Recheck the eccentric rod alignment and ensure that the valve gear is correctly timed.

- Excessive Noise: Unusual noises, such as knocking or grinding, may be a sign of improper timing or misaligned components. Inspect the valve gear and adjust as needed to eliminate these noises.

- Uneven Piston Movement: If the pistons are not moving evenly, it may indicate a problem with the timing or the valve gear. Ensure that the timing marks are correctly aligned and that the valve gear is functioning smoothly.

Maintenance and Care for Optimal Performance

Regular maintenance and care are essential for keeping the Accucraft Ruby in optimal condition. Proper maintenance helps prevent timing issues and ensures that the locomotive continues to perform well.

- Regular Cleaning: Keep the locomotive clean to prevent dirt and debris from affecting the timing and overall performance. Regularly inspect and clean the valve gear and piston components.

- Lubrication: Ensure that all moving parts are adequately lubricated. Regular lubrication helps reduce wear and tear on the components and ensures smooth operation.

- Check for Wear: Periodically check for signs of wear or damage to the valve gear and piston components. Replace any worn or damaged parts as needed to maintain optimal performance.

Conclusion

Setting the timing on an Accucraft Ruby is a detailed process that requires careful adjustment and attention to detail. By understanding the basics of steam locomotive timing, preparing the engine properly, and following the step-by-step guide, you can ensure that your Accucraft Ruby operates smoothly and efficiently.

Remember that regular maintenance and care are crucial for keeping the locomotive in top condition. Furthermore, by following these guidelines and addressing any issues promptly, you can enjoy the exceptional performance and reliability of your Accucraft Ruby for years to come.