The Evolution of Manufacturing: How Robotics is Shaping the Future of Production

It’s essential for manufacturers to understand how robotics is reshaping the industry. The evolution of manufacturing has seen a significant shift from manual labor to automation, with robots playing a pivotal role in this transformation.

These machines are not just tools; they are revolutionizing production processes, making them more efficient, precise, and adaptable to the demands of the modern market. Choosing an assembly robot for your production line is crucial and can significantly impact your operation’s success.

Robots can perform tasks with a level of consistency and speed that is unattainable by human hands. They are particularly effective in repetitive tasks that require precision, such as assembling components, where even the smallest mistake can lead to significant defects.

By integrating robots into your assembly line, you increase efficiency and improve the quality of your products, reducing the margin for error.

Key Factors in Choosing an Assembly Robot

When choosing an assembly robot, several factors must be considered to ensure that it is the best fit for your specific production needs. The first factor to consider is the robot’s task type.

Different robots are designed for different applications. For example, if your production line involves assembling small, delicate components, you’ll need a robot that excels in precision and fine motor control.

On the other hand, if your operation requires handling larger, heavier parts, you’ll want a more robust robot capable of lifting and manipulating heavier objects.

Another important consideration is the robot’s flexibility. In today’s manufacturing environment, production lines need to be adaptable to change. This might involve switching between different product types or adjusting to varying production volumes.

A flexible robot that can be easily reprogrammed to handle different tasks without significant downtime is invaluable in such scenarios. This adaptability not only maximizes the robot’s utility but also ensures that your production line can keep up with changing market demands.

Cost is another critical factor. While the initial investment in robotics can be substantial, weighing this against the long-term benefits is important. Robots can operate continuously, increasing production output and reducing labor costs.

Additionally, the precision and consistency they bring to the production process can result in fewer defects and less waste, further contributing to cost savings.

The Impact of AI-Assisted App Creation on Manufacturing

In addition to robotics, artificial intelligence (AI) is making waves in manufacturing, particularly in the realm of app creation. AI-assisted app creation transforms how you can manage and optimize your production processes.

These AI-powered apps are designed to streamline various aspects of manufacturing, from monitoring production lines to predictive maintenance, ensuring that your operations run smoothly.

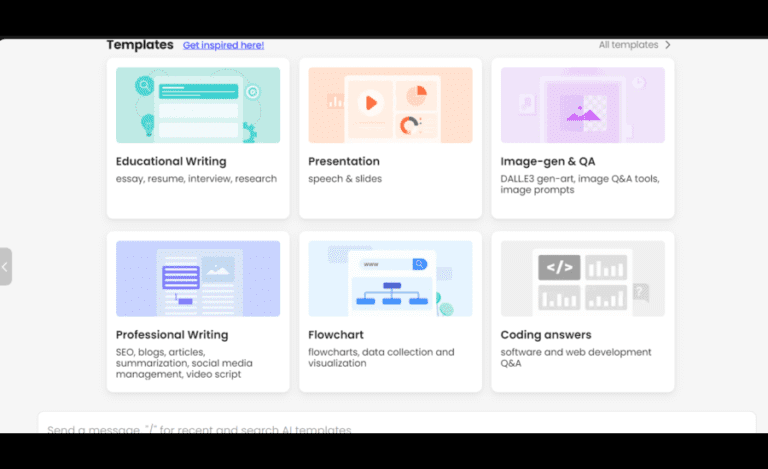

AI-assisted app creation allows you to develop custom applications tailored to your specific manufacturing needs. These apps can integrate with your robotic systems, providing real-time data on performance, identifying bottlenecks, and suggesting improvements.

For instance, if a particular robot on your assembly line is underperforming, the app can alert you to the issue and recommend adjustments, such as recalibrating the robot or changing its operational parameters.

Moreover, AI-assisted apps can help in predictive maintenance, a crucial aspect of modern manufacturing. By analyzing data from your robotic systems, these apps can predict when a component will likely fail, allowing you to perform maintenance before a breakdown occurs.

This proactive approach minimizes downtime and extends your equipment’s lifespan, resulting in significant cost savings.

Integrating Robotics and AI for a Competitive Edge

It’s essential to integrate robotics with AI-assisted app creation. This combination allows you to create a more dynamic and responsive production line capable of adapting to changes quickly and efficiently.

By leveraging the strengths of both robotics and AI, you can optimize your production processes, reduce waste, and improve product quality.

One key advantage of this integration is the ability to make data-driven decisions. AI-powered apps collect and analyze data from your robotic systems, gaining valuable insights into your operations.

These insights enable you to identify inefficiencies, predict future trends, and make informed decisions that enhance productivity and profitability.

Furthermore, the integration of robotics and AI can lead to greater innovation. As your production line becomes more efficient, you can focus on developing new products or improving existing ones, ensuring that your business remains at the forefront of the industry.

Conclusion: Robotics and AI Driving the Future of Manufacturing

The integration of robotics and AI is driving the evolution of manufacturing. When choosing an assembly robot, it’s crucial to consider factors such as task specificity, flexibility, and cost to ensure you make the right choice for your production needs.

Additionally, AI-assisted app creation is transforming how you manage and optimize your operations, providing real-time insights and predictive capabilities that enhance efficiency and reduce costs. Integrating robotics with AI allows you to position your manufacturing operation for success in an increasingly competitive industry.