Embracing High-Speed Spindles in Modern Manufacturing

In the rapidly evolving manufacturing landscape, where precision and speed are not just desired but essential, high-speed spindles have emerged as vital components in the quest for operational excellence. These spindles are redefining efficiency and quality, playing a transformative role in numerous industries seeking to enhance their production capabilities and maintain a robust competitive edge. By optimizing machining processes through their advanced engineering, high-speed spindles allow manufacturers to achieve unprecedented precision, which is increasingly critical in today’s fast-paced market.

Key Takeaways

- Understanding the benefits of high-speed spindles can fundamentally revolutionize manufacturing processes, dramatically increasing efficiency and product quality.

- Identify key industries that leverage precision and efficiency and are driven forward by this advanced technology.

- Discover the role of high-speed spindles in supporting sustainable manufacturing practices, which are crucial for meeting modern eco-friendly goals.

What Are High-Speed Spindles?

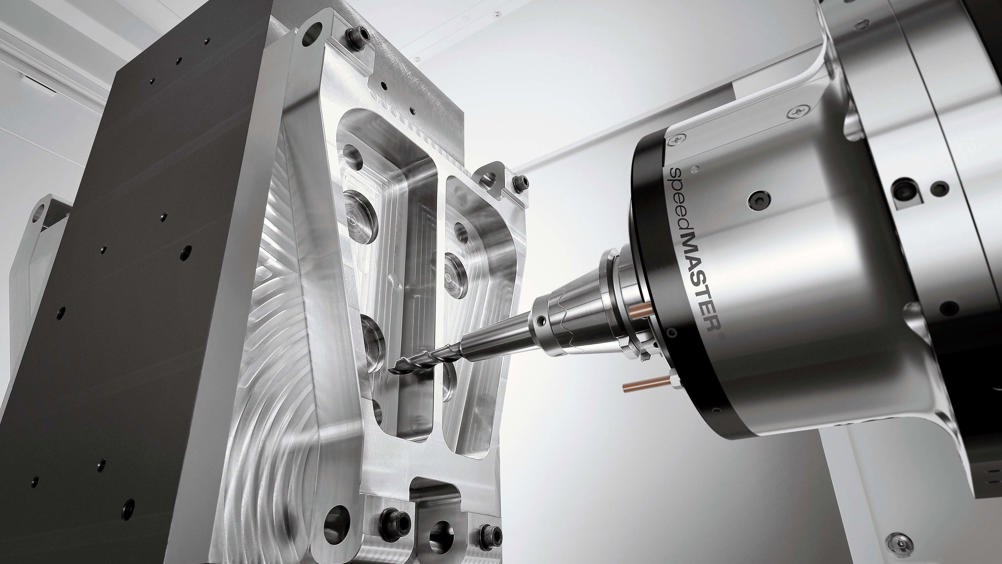

High-speed spindles, central to modern industrial applications, are celebrated for their ability to operate at remarkably high rotational speeds. Traditionally, machining processes relied on slower, less efficient spindles that, while reliable, lacked the prowess needed for today’s exacting standards. Enter the high-speed spindle: a marvel of engineering that offers faster removal rates and unprecedented machining precision. These impressive machines are marked by their compact, robust design and unparalleled capability for maximizing machining efficiency, making them indispensable across a spectrum of manufacturing sectors that demand intricate and complex work. To further explore how these dynamic tools can revolutionize your production line, learn more about their significant impact on manufacturing processes.

Benefits of High-Speed Spindles in Manufacturing

Integrating high-speed spindles into the manufacturing process introduces a host of transformative advantages, directly contributing to competitive superiority. Perhaps the most significant of these benefits is enhanced production efficiency achieved through drastically reduced cycle times. Shorter cycle times mean higher throughput, enabling companies to bring products to market more quickly, which is vital in maintaining a leading position in today’s competitive environment. Additionally, the high-precision machining capabilities afforded by these spindles minimize errors and rework, resulting in superior product quality. This heightened quality often translates into fewer customer returns and increased customer satisfaction. Implementing high-speed spindles can also contribute to substantial cost reductions due to decreased material wastage and energy consumption, playing a significant role in improving the bottom line and supporting sustainable practices.

Industries Leveraging High-Speed Spindle Technology

Aerospace Industry Advancements

High-speed spindles significantly enhance production capabilities in the aerospace industry, where precision and strict tolerance specifications are non-negotiable. Due to their ability to efficiently machine complex components such as turbine blades and airframes, they enable the use of tough materials like titanium and advanced composites. By incorporating high-speed spindles, aerospace manufacturers can maintain and elevate their standards of excellence, meeting stringent regulatory demands and increasing performance expectations of the modern aerospace sector.

Automotive Manufacturing Improvements

The automotive industry similarly benefits from high-speed spindle technology’s increased precision and capability. This industry values tight tolerances and smooth finishes on components such as engine parts and gearboxes, as they directly influence vehicle performance and durability. With these spindles, manufacturers can achieve these goals more efficiently, improving the reliability and lifespan of automotive parts. This ultimately contributes to developing higher-quality vehicles that meet ever-evolving consumer expectations and stringent safety and performance regulations.

Electronics Industry Precision and Miniaturization

As consumer demand for smaller, more complex electronic devices grows, high-speed spindles have become indispensable tools in the electronics manufacturing industry. These spindles provide the extreme precision required for delicate detailing during the production processes of gadgets and semiconductor devices. The accurate machining they enable is critical for adhering to the stringent quality control standards that define the electronics industry, ensuring the production of reliable and intricately detailed components that power modern technological innovation.

Sustainability and Environmental Impact

Beyond their operational benefits, high-speed spindles also contribute to sustainability efforts by reducing waste and energy consumption in manufacturing processes. The heightened speed at which these spindles operate means decreased energy usage per unit, which aligns well with sustainable manufacturing practices. Furthermore, the precision enabled by spindle technology significantly reduces material wastage, which aligns with global efforts for eco-friendly manufacturing processes. By minimizing the environmental footprint and long-term costs associated with production, companies can meet modern environmental standards and regulations while fostering more sustainable industrial practices.

Challenges and Considerations

Despite the numerous advantages, implementing high-speed spindles requires careful consideration of certain challenges. The initial investment can be substantial, representing a significant financial commitment, especially for small to medium-sized businesses. Moreover, seamlessly integrating these spindles into existing processes requires strategic planning in terms of technological compatibility and the need for workforce training. Industry leaders must remain informed about the latest challenges in precision manufacturing to effectively navigate these potential hurdles, ensuring successful implementation and maximizing the return on investment in high-speed spindle technology.

Future Trends in High-Speed Spindle Technology

The horizon for spindle technology is promising, with trends pointing towards deeper integration with emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT). These integrations are anticipated to usher in a new era of smart manufacturing solutions characterized by real-time production monitoring, predictive maintenance, and heightened operational efficiency. As global manufacturing landscapes change rapidly, high-speed spindles are expected to play an increasingly central role, shaping innovative and efficient production methods that respond to evolving market demands and technological advancements.

Conclusion: Preparing for Tomorrow’s Manufacturing Needs

In conclusion, high-speed spindles are a cornerstone of contemporary manufacturing advancements, offering unmatched precision, efficiency, and support for sustainable practices. Their ability to enhance existing manufacturing capabilities while preparing industries for future trends and challenges positions them as essential tools in the modern production landscape. As more sectors embrace the advantages of high-speed spindle technology, they not only enhance their current operations but also pave the way for leveraging cutting-edge advancements that maintain their competitive edge. The time is ripe for industries to invest in and adapt to this revolutionary technology, ensuring preparedness and success in meeting the ever-evolving demands and opportunities of tomorrow’s industrial landscape.