AI in Production Planning and Operational Efficiency: Revolutionizing Manufacturing

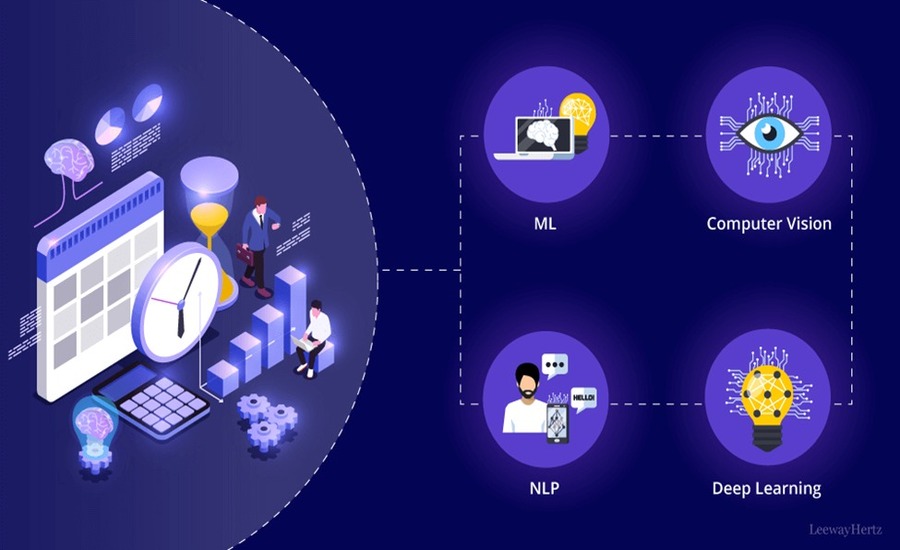

rtificial intelligence (AI) is transforming industries, and manufacturing is no exception. In particular, AI is playing a pivotal role in optimizing production planning and improving operational efficiency. As industries look to stay competitive in a rapidly changing market, integrating AI-driven solutions offers significant advantages for streamlining processes, reducing costs, and enhancing productivity.

In this article, we will explore how AI is reshaping production planning and operational efficiency, the key benefits it provides, and the future trends that will define the manufacturing landscape.

AI in Production Planning: Enhancing Manufacturing Precision

Production planning is a complex process that involves coordinating various activities, including inventory management, workforce allocation, and scheduling of manufacturing tasks. Traditionally, this process has been time-consuming and susceptible to human error. AI technology, however, has significantly streamlined production planning, resulting in improved accuracy, reduced lead times, and optimized resource allocation.

AI-Driven Demand Forecasting

Accurate demand forecasting is essential for effective production planning. AI uses machine learning algorithms to analyze historical data, market trends, and customer behaviors, enabling manufacturers to predict demand with high accuracy. This allows for better planning of production schedules, inventory levels, and resource allocation, ultimately minimizing waste and maximizing efficiency.

AI-driven demand forecasting also helps businesses quickly adapt to changes in market conditions, such as seasonal fluctuations or unexpected shifts in customer preferences. By predicting demand in real-time, manufacturers can avoid overproduction or stock shortages, leading to more efficient production cycles.

Real-Time Production Scheduling

One of the most significant ways AI improves production planning is through real-time production scheduling. AI systems can optimize production lines by analyzing production data, equipment performance, and workforce availability. By making adjustments in real-time, AI ensures that production schedules are always aligned with current conditions, minimizing delays and improving overall output.

AI in production planning also allows for better contingency planning, as the system can automatically reroute resources or reschedule tasks when disruptions occur, such as machine breakdowns or supply chain issues. This level of flexibility enhances the responsiveness of production lines and keeps operations running smoothly.

Optimized Inventory Management

AI enhances production planning by improving inventory management processes. Traditional inventory management methods often lead to overstocking or understocking due to inaccurate forecasts. With AI, manufacturers can track inventory levels in real-time and use predictive analytics to determine when to reorder supplies, ensuring that inventory levels are always optimal.

By integrating AI into inventory management systems, manufacturers can reduce holding costs, prevent stockouts, and avoid unnecessary production delays. This leads to more streamlined operations and significant cost savings.

AI for Operational Efficiency: Streamlining Processes for Maximum Output

In addition to optimizing production planning, AI plays a vital role in enhancing overall operational efficiency. By automating routine tasks, improving decision-making, and providing valuable insights, AI empowers manufacturers to achieve greater levels of productivity and competitiveness.

Automation of Repetitive Tasks

AI-driven automation is at the core of improving operational efficiency. By automating repetitive tasks, such as quality control checks, data entry, and machine monitoring, AI allows workers to focus on higher-value activities. This not only reduces the likelihood of errors but also increases the speed at which tasks are completed.

Robots and AI-powered machines can perform repetitive, time-consuming tasks with unparalleled precision and consistency. This level of automation reduces the risk of human error, lowers operational costs, and ensures that products meet quality standards without manual intervention.

Predictive Maintenance for Enhanced Equipment Performance

Machine downtime is one of the biggest challenges in manufacturing, leading to lost productivity and increased costs. AI mitigates this issue through predictive maintenance, which involves using sensors and machine learning algorithms to monitor equipment performance in real-time. AI systems can detect patterns that indicate potential equipment failures and predict when maintenance is required, allowing for timely intervention before a breakdown occurs.

By implementing AI-driven predictive maintenance, manufacturers can minimize unplanned downtime, extend the lifespan of equipment, and reduce the costs associated with emergency repairs. This proactive approach to maintenance ensures that production lines operate at peak efficiency.

Optimizing Workforce Management

AI-powered systems can analyze workforce data to optimize labor allocation and scheduling. By evaluating factors such as employee skills, productivity, and shift availability, AI ensures that the right workers are assigned to the right tasks at the right time. This helps manufacturers maintain balanced workloads, prevent bottlenecks, and maximize overall productivity.

Moreover, AI can assist in workforce training and development by identifying skill gaps and recommending tailored training programs for employees. This leads to a more skilled workforce, which in turn enhances operational efficiency.

Similarly, integrating advanced AI in logistics provides businesses with the confidence to manage complex transportation networks with ease, ensuring smooth operations, timely deliveries, and reduced operational disruptions.

Enhancing Supply Chain Visibility

AI for operational efficiency enhances supply chain visibility. By using AI to analyze data from suppliers, logistics partners, and production facilities, manufacturers can gain real-time insights into their entire supply chain. This level of visibility allows for better decision-making, improved coordination between suppliers and production teams, and faster response times to disruptions.

With AI-driven supply chain visibility, manufacturers can reduce lead times, lower transportation costs, and improve customer satisfaction by ensuring that products are delivered on time and at the right cost.

Benefits of AI in Production Planning and Operational Efficiency

The integration of AI in production planning and operational efficiency offers a wide range of benefits for manufacturers:

- Improved Accuracy: AI eliminates human errors by automating complex calculations and decision-making processes, resulting in more accurate demand forecasts, production schedules, and inventory management.

- Cost Savings: AI-driven automation reduces the need for manual labor, minimizes equipment downtime, and optimizes resource allocation, leading to significant cost savings.

- Faster Time-to-Market: AI allows manufacturers to streamline production processes, reduce lead times, and respond more quickly to changes in market demand, ensuring faster delivery of products to market.

- Enhanced Product Quality: By automating quality control checks and implementing predictive maintenance, AI helps ensure that products meet high-quality standards, reducing the likelihood of defects or recalls.

- Sustainability: AI-powered optimization of resources and inventory levels reduces waste, energy consumption, and material use, contributing to more sustainable manufacturing practices.

- Scalability: AI systems are scalable, allowing manufacturers to adjust production levels based on changing demand without compromising efficiency or quality.

Challenges of Implementing AI in Manufacturing

While the benefits of AI are significant, there are also challenges associated with its implementation in production planning and operational efficiency:

- Integration Complexity: Integrating AI into existing production systems and processes can be complex, requiring substantial investments in technology, infrastructure, and training.

- Data Security: The use of AI relies heavily on the collection and analysis of data, which raises concerns about data privacy and cybersecurity. Manufacturers must ensure that they have robust data protection measures in place.

- Skill Gaps: AI implementation requires a workforce with expertise in data analytics, machine learning, and AI technologies. Manufacturers may need to invest in upskilling employees or hire new talent to successfully adopt AI solutions.

- High Initial Costs: While AI leads to cost savings in the long run, the initial investment required for AI technologies, including software, hardware, and implementation, can be substantial.

Future Trends in AI for Manufacturing

The future of AI in production planning and operational efficiency is bright, with several emerging trends set to further revolutionize manufacturing:

- AI and IoT Integration: The integration of AI with the Internet of Things (IoT) will create smart factories where machines communicate with each other in real-time, optimizing production processes and reducing waste.

- AI-Driven Autonomous Manufacturing: Fully autonomous manufacturing plants, powered by AI, will become more prevalent, allowing for lights-out manufacturing with minimal human intervention.

- AI for Sustainable Manufacturing: AI will play a crucial role in promoting sustainable manufacturing practices by optimizing energy use, reducing waste, and lowering carbon emissions.

- Collaborative AI Systems: AI systems that work alongside human workers will become more sophisticated, enabling enhanced collaboration between machines and humans on the factory floor.

Conclusion

AI is reshaping production planning and operational efficiency in the manufacturing sector, offering unprecedented levels of accuracy, speed, and productivity. By automating tasks, improving demand forecasting, and enhancing equipment performance, AI is enabling manufacturers to stay competitive in an increasingly complex and fast-paced market.

While challenges exist, the benefits of integrating AI into manufacturing processes are clear, from cost savings to improved product quality and sustainability. As AI technology continues to evolve, manufacturers that embrace these innovations will be well-positioned to lead in the future of smart manufacturing.